A little history

The AR-88 was a listening post receiver used during WW2 to listen to German radio communications. It was made by RCA for the war effort. The designers of the radio were told “to pull all the stops out” and the budget for the research and design for this radio was enormous. The result is a radio that is stable and is still more sensitive than a large amount of modern receivers.

The repair:

The repair I did on my AR-88 was preventative maintenance (as well as adding the meter circuit). The first step was to get the nearly 50kg rig onto the floor and take it out of its case. It slides out on two rails which would have usually worked well except, thanks to the age of the rig, they were covered in rust and didn’t run smoothly. After I got the rig out of the case, I sprayed WD40 on the rails and cleaned the rust off which worked great.

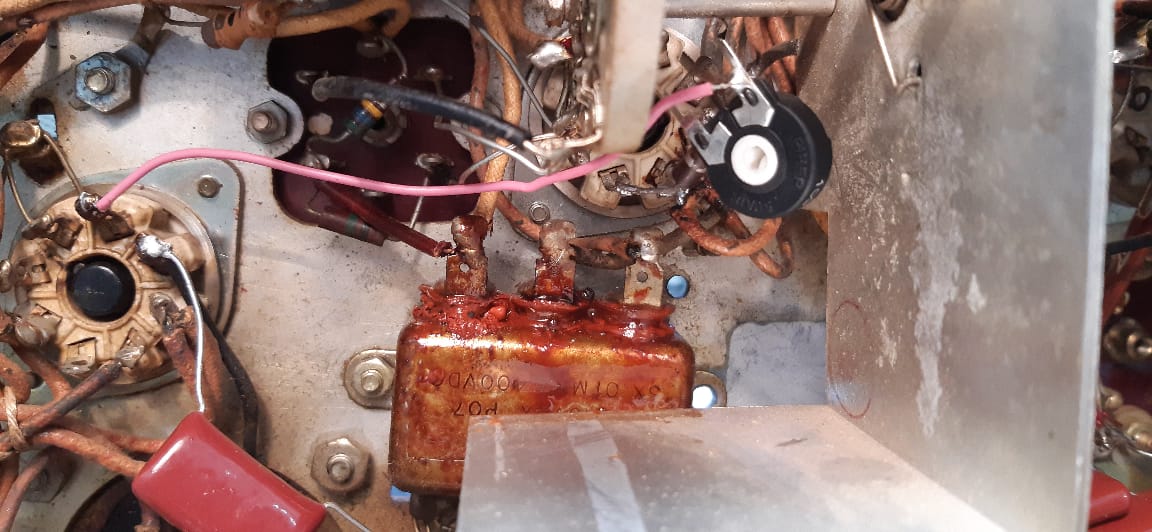

I then put the radio onto my bench with the help of my parents and started cleaning it. After getting the dust off of it, I desoldered the wires going to the chokes and cleaned the leaking oil off of the chassis and chokes. The oil came from the chokes since when they had gotten hot, the oil inside had liquified and leaked out. This problem would be resolved later when I replaced the capacitors with better ones reducing the load on the choke.

After doing all the major cleaning I removed the knobs and the front panel and cleaned it up with Handy Andy and soapy water (be careful with leaving the Handy Andy on for too long, it can damage the paint!). While carrying the front panel back to the garage I fell down the stairs and the mechanical dial lock broke as I dropped the roughly 10kg steel plate on the floor (it’s about a cm thick). The front panel wasn’t damaged besides the dial lock screw which I am going to re-make on a lathe when I get access to one.

After the cleaning process, I started work on replacing old degrading components (the radio is around 80 years old and so are the components). I replaced the PCB-filled tub capacitors (PCB oil is carcinogenic and the seals on the capacitor tubs are rubber and have degraded and leak). There are six of them in the AR-88 all of which have to be replaced. It is EXTREMELY important to wear gloves while handling them. There is another oil-filled capacitor bank which I left in there because it was in great condition and wasn’t leaking (and wasn’t full of PCB oil). I replaced the tub capacitors with foil capacitors which worked great. The filament voltage dropping resistors (100ohms and 150ohms at 10w) were corroded and were replaced. A few resistors and micamold capacitors (cheaper, slightly worse mica capacitors) around the rig replaced. There is a capacitor that couples the audio out of the audio output section into the audio transformer. If this capacitor fails as a short, it puts B+ on one side of the transformer and ground on the other side blowing up the rare audio transformer. It’s extremely important to replace.

After having replaced all the old components that were degrading or prone to failure, I started work on the meter circuit. During war time production, there was a shortage of signal strength meters and as a result they just put a cover over the hole where the meter went. My AR-88 came with a meter installed and the wiring for the meter in the lacing, but both sides of the meter grounded. I still haven’t found out why since the wiring and meter are definitely factory original, but the rest of the meter circuitry wasn’t there (a potentiometer, a resistor and a capacitor). I have no idea how this happened…

After installing the meter and calibrating it by getting the needle all the way to the left with the antenna input shorted (the meter’s mechanical zero set to the right instead of the normal left). I then performed a full alignment.

The electrical restoration is complete and all that needs to be done is to re-machine the dial lock knob and paint it.

Leave a Reply